Important Product Categories of Quartz Fiber Casing

I. Introduction

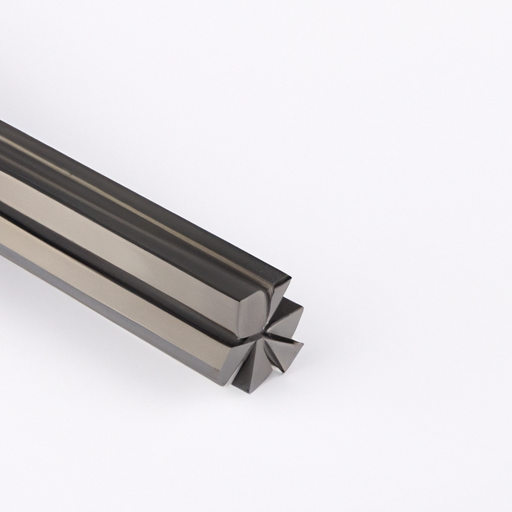

A. Definition of Quartz Fiber Casing

Quartz fiber casing refers to protective and insulating materials made from quartz fibers, which are derived from high-purity silica. These casings are known for their exceptional thermal stability, electrical insulation properties, and chemical resistance, making them suitable for a wide range of industrial applications.

B. Importance of Quartz Fiber in Various Industries

Quartz fiber has gained significant traction in industries such as aerospace, electronics, telecommunications, and chemical processing. Its unique properties allow it to withstand extreme conditions, making it an ideal choice for applications that require durability and reliability. As industries continue to evolve, the demand for advanced materials like quartz fiber casing is expected to grow.

C. Purpose of the Article

This article aims to explore the important product categories of quartz fiber casing, highlighting their properties, applications, and market trends. By understanding these categories, stakeholders can make informed decisions regarding the use of quartz fiber in their respective fields.

II. Overview of Quartz Fiber

A. Composition and Properties

1. Chemical Structure

Quartz fiber is primarily composed of silicon dioxide (SiO2), which gives it its unique properties. The crystalline structure of quartz contributes to its strength and stability, making it resistant to thermal and chemical degradation.

2. Thermal Stability

One of the standout features of quartz fiber is its ability to withstand high temperatures. It can maintain its integrity in environments exceeding 1,000 degrees Celsius, making it suitable for applications in high-temperature settings.

3. Electrical Insulation

Quartz fiber also exhibits excellent electrical insulation properties. It has a high dielectric strength, which makes it an ideal choice for electrical and electronic applications where insulation is critical.

B. Manufacturing Process

1. Raw Material Sourcing

The production of quartz fiber begins with the sourcing of high-purity silica. This raw material is essential for ensuring the quality and performance of the final product.

2. Production Techniques

The manufacturing process involves melting silica at high temperatures and then drawing it into fibers. Various techniques, such as the flame or electric arc method, can be employed to produce quartz fibers of different diameters and properties.

3. Quality Control Measures

Quality control is crucial in the production of quartz fiber casing. Manufacturers implement rigorous testing protocols to ensure that the fibers meet industry standards for thermal stability, electrical insulation, and chemical resistance.

III. Key Product Categories of Quartz Fiber Casing

A. High-Temperature Insulation

1. Applications in Aerospace

In the aerospace industry, high-temperature insulation made from quartz fiber is used in various components, including engine parts and thermal protection systems. The ability to withstand extreme temperatures is critical for ensuring the safety and performance of aircraft.

2. Use in Industrial Furnaces

Quartz fiber casing is also utilized in industrial furnaces, where it serves as insulation for heating elements and protective barriers. Its thermal stability helps maintain efficient operation and energy savings.

3. Benefits of High-Temperature Insulation

The benefits of high-temperature insulation include reduced heat loss, improved energy efficiency, and enhanced safety. By using quartz fiber casing, industries can achieve better performance while minimizing operational costs.

B. Electrical Insulation

1. Role in Electronics and Electrical Equipment

Quartz fiber casing plays a vital role in the electronics industry, where it is used to insulate wires, circuit boards, and other electrical components. Its high dielectric strength ensures reliable performance in various applications.

2. Advantages Over Traditional Insulation Materials

Compared to traditional insulation materials, quartz fiber offers superior thermal and electrical properties. It is less prone to degradation over time, making it a more durable choice for long-term applications.

3. Case Studies of Successful Applications

Numerous case studies highlight the successful use of quartz fiber casing in electrical applications. For instance, its use in high-voltage transformers has demonstrated improved performance and longevity compared to conventional insulation materials.

C. Chemical Resistance Casings

1. Importance in Chemical Processing Industries

In chemical processing industries, quartz fiber casing is essential for protecting equipment from corrosive substances. Its chemical resistance properties make it suitable for use in environments where traditional materials would fail.

2. Properties that Enhance Chemical Resistance

The inherent properties of quartz fiber, such as its low porosity and high thermal stability, contribute to its chemical resistance. This makes it an ideal choice for applications involving acids, bases, and other harsh chemicals.

3. Examples of Use in Harsh Environments

Quartz fiber casing is commonly used in chemical reactors, storage tanks, and piping systems. Its ability to withstand extreme conditions ensures the safety and efficiency of chemical processes.

D. Optical Fiber Casing

1. Significance in Telecommunications

In the telecommunications sector, quartz fiber casing is crucial for protecting optical fibers. Its transparency and low attenuation properties enhance signal transmission, making it a preferred choice for high-speed communication networks.

2. Advantages of Quartz Fiber in Optical Applications

Quartz fiber offers several advantages in optical applications, including high tensile strength, resistance to environmental factors, and compatibility with various fiber optic technologies.

3. Innovations in Optical Fiber Technology

Recent innovations in optical fiber technology have led to the development of advanced quartz fiber casings that improve performance and reduce signal loss. These advancements are driving the growth of the telecommunications industry.

E. Composite Materials

1. Integration with Other Materials

Quartz fiber is often integrated with other materials to create composite products that leverage the strengths of both. This integration enhances the overall performance and versatility of the final product.

2. Applications in Automotive and Aerospace Industries

In the automotive and aerospace industries, composite materials made from quartz fiber are used in lightweight structures, improving fuel efficiency and performance. These materials are increasingly being adopted in high-performance applications.

3. Future Trends in Composite Quartz Fiber Products

The future of composite quartz fiber products looks promising, with ongoing research focused on developing new formulations and applications. Innovations in manufacturing techniques are expected to further enhance the performance of these materials.

IV. Market Trends and Demand

A. Growth of the Quartz Fiber Market

1. Key Drivers of Market Growth

The quartz fiber market is experiencing significant growth, driven by the increasing demand for high-performance materials in various industries. The need for lightweight, durable, and heat-resistant materials is propelling the adoption of quartz fiber casing.

2. Emerging Markets and Opportunities

Emerging markets, particularly in Asia-Pacific and Latin America, present new opportunities for quartz fiber manufacturers. As industries in these regions expand, the demand for advanced materials is expected to rise.

B. Challenges Facing the Industry

1. Competition from Alternative Materials

Despite its advantages, quartz fiber faces competition from alternative materials such as carbon fiber and fiberglass. Manufacturers must continue to innovate and demonstrate the unique benefits of quartz fiber to maintain market share.

2. Environmental Concerns and Sustainability

Sustainability is becoming a critical concern in the materials industry. Manufacturers are exploring eco-friendly production methods and recycling options to address environmental challenges associated with quartz fiber production.

C. Future Outlook

1. Innovations on the Horizon

The future of quartz fiber casing is bright, with ongoing research focused on enhancing its properties and expanding its applications. Innovations in manufacturing processes and material formulations are expected to drive growth in the coming years.

2. Predictions for Market Evolution

As industries continue to evolve, the demand for quartz fiber casing is likely to increase. The integration of advanced technologies and the focus on sustainability will shape the future of the quartz fiber market.

V. Conclusion

A. Summary of Key Points

Quartz fiber casing is a versatile and high-performance material with applications across various industries. Its unique properties, including thermal stability, electrical insulation, and chemical resistance, make it an ideal choice for demanding environments.

B. The Role of Quartz Fiber Casing in Advancing Technology

As technology continues to advance, the role of quartz fiber casing will become increasingly important. Its ability to meet the challenges of modern applications positions it as a key material in the development of innovative solutions.

C. Final Thoughts on the Importance of Continued Research and Development

Continued research and development in quartz fiber technology are essential for unlocking new applications and improving existing products. By investing in innovation, industries can harness the full potential of quartz fiber casing to drive progress and enhance performance.

VI. References

A. Academic Journals

- Journal of Materials Science

- Composites Science and Technology

B. Industry Reports

- Global Quartz Fiber Market Report

- Aerospace Materials Market Analysis

C. Manufacturer Websites and Product Catalogs

- [Manufacturer A](#)

- [Manufacturer B](#)

This comprehensive exploration of quartz fiber casing highlights its significance across various industries and underscores the importance of continued innovation in this field. As demand grows, so too will the opportunities for quartz fiber to play a pivotal role in advancing technology and improving performance in numerous applications.