Popular Models of Polyacrylate Fiberglass Sleeves

I. Introduction

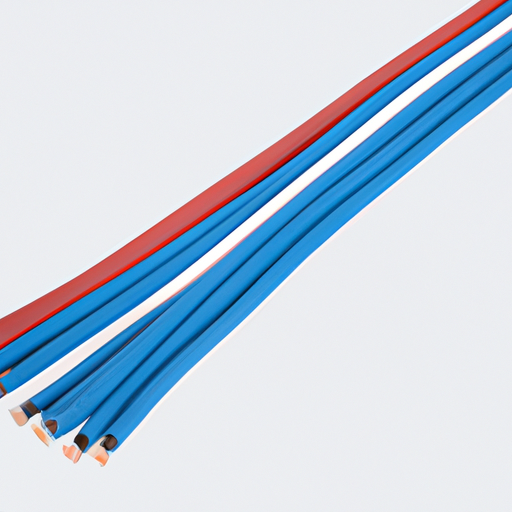

Polyacrylate fiberglass sleeves are specialized protective coverings made from a combination of fiberglass and polyacrylate materials. These sleeves are designed to provide insulation, protection, and reinforcement in various applications across multiple industries. Their unique properties make them essential in environments where high temperatures, chemical exposure, and mechanical stress are prevalent. This article aims to explore the popular models of polyacrylate fiberglass sleeves, their specifications, applications, and advantages, as well as future trends in this innovative field.

II. Overview of Polyacrylate Fiberglass Sleeves

A. Composition and Properties

Polyacrylate fiberglass sleeves are composed of two primary materials: fiberglass reinforcement and a polyacrylate coating.

1. **Fiberglass Reinforcement**: Fiberglass is known for its high tensile strength and lightweight properties. It provides structural integrity to the sleeves, making them resistant to tearing and deformation under stress.

2. **Polyacrylate Coating**: The polyacrylate layer offers excellent thermal and chemical resistance. This coating enhances the sleeve's ability to withstand extreme temperatures and harsh chemicals, making it suitable for various industrial applications.

B. Benefits of Using Polyacrylate Fiberglass Sleeves

The use of polyacrylate fiberglass sleeves comes with several benefits:

1. **Thermal Resistance**: These sleeves can withstand high temperatures, making them ideal for applications in automotive and aerospace industries where heat exposure is common.

2. **Chemical Resistance**: The polyacrylate coating provides excellent resistance to a wide range of chemicals, ensuring the integrity of the materials being protected.

3. **Mechanical Strength**: The combination of fiberglass and polyacrylate results in a product that is both strong and flexible, capable of enduring mechanical stress without compromising performance.

4. **Flexibility and Durability**: Polyacrylate fiberglass sleeves are designed to be flexible, allowing for easy installation and adaptability to various shapes and sizes. Their durability ensures a long service life, reducing the need for frequent replacements.

III. Popular Models of Polyacrylate Fiberglass Sleeves

A. Model 1: High-Temperature Resistant Sleeves

1. **Specifications**: These sleeves can typically withstand temperatures up to 500°F (260°C) and are designed for applications that involve direct heat exposure.

2. **Applications**: Commonly used in automotive exhaust systems, aerospace components, and industrial machinery.

3. **Advantages**: Their high-temperature tolerance ensures that they maintain structural integrity and performance even in extreme conditions, reducing the risk of failure.

B. Model 2: Chemical-Resistant Sleeves

1. **Specifications**: These sleeves are formulated to resist a wide range of chemicals, including acids, bases, and solvents.

2. **Applications**: Ideal for use in chemical processing plants, laboratories, and environments where exposure to harsh substances is common.

3. **Advantages**: The chemical resistance of these sleeves protects underlying materials from corrosion and degradation, extending the lifespan of equipment and components.

C. Model 3: Electrical Insulation Sleeves

1. **Specifications**: Designed to provide electrical insulation, these sleeves can withstand voltages up to 1,000 volts.

2. **Applications**: Widely used in electrical wiring, connectors, and components in the electronics industry.

3. **Advantages**: Their electrical insulation properties help prevent short circuits and electrical failures, ensuring the safety and reliability of electrical systems.

D. Model 4: Fire-Resistant Sleeves

1. **Specifications**: These sleeves are treated with fire-retardant materials, allowing them to withstand flames and high temperatures.

2. **Applications**: Commonly used in industries such as aerospace, automotive, and construction, where fire safety is a critical concern.

3. **Advantages**: Fire-resistant sleeves provide an additional layer of safety, reducing the risk of fire-related incidents and protecting valuable equipment.

E. Model 5: Customizable Sleeves

1. **Specifications**: These sleeves can be tailored to meet specific requirements, including size, thickness, and color.

2. **Applications**: Suitable for a wide range of industries, including automotive, aerospace, and manufacturing, where unique specifications are often needed.

3. **Advantages**: Customizable sleeves allow for greater flexibility in design and application, ensuring that specific needs are met without compromising performance.

IV. Comparison of Popular Models

A. Performance Metrics

1. **Temperature Tolerance**: High-temperature resistant sleeves excel in extreme heat, while fire-resistant sleeves offer additional protection against flames.

2. **Chemical Compatibility**: Chemical-resistant sleeves are specifically designed to withstand harsh substances, making them the best choice for chemical applications.

3. **Mechanical Properties**: All models provide excellent mechanical strength, but customizable sleeves can be designed to meet specific mechanical requirements.

B. Cost Analysis

The cost of polyacrylate fiberglass sleeves varies based on the model and specifications. High-temperature and chemical-resistant sleeves may be more expensive due to their specialized properties, while customizable options may incur additional costs for design and manufacturing.

C. User Feedback and Reviews

User feedback often highlights the durability and effectiveness of polyacrylate fiberglass sleeves in various applications. Many users appreciate the flexibility and ease of installation, while others note the long-lasting performance of these materials in demanding environments.

V. Applications of Polyacrylate Fiberglass Sleeves

A. Automotive Industry

In the automotive sector, polyacrylate fiberglass sleeves are used to protect wiring, hoses, and components from heat and chemical exposure. Their thermal and chemical resistance ensures the longevity and reliability of automotive systems.

B. Aerospace Industry

Aerospace applications require materials that can withstand extreme conditions. Polyacrylate fiberglass sleeves are used in aircraft wiring, insulation, and component protection, ensuring safety and performance in flight.

C. Electrical and Electronics

In the electrical and electronics industries, these sleeves provide insulation and protection for wiring and components, preventing electrical failures and enhancing safety.

D. Industrial Manufacturing

Polyacrylate fiberglass sleeves are widely used in industrial manufacturing to protect machinery and equipment from heat, chemicals, and mechanical stress, ensuring efficient operation.

E. Construction and Insulation

In construction, these sleeves are used for insulation and protection of pipes and wiring, contributing to energy efficiency and safety in buildings.

VI. Future Trends in Polyacrylate Fiberglass Sleeves

A. Innovations in Material Science

Advancements in material science are leading to the development of even more effective polyacrylate fiberglass sleeves. Innovations may include enhanced thermal and chemical resistance, as well as improved mechanical properties.

B. Sustainability and Eco-Friendly Options

As industries move towards sustainability, there is a growing demand for eco-friendly materials. Future polyacrylate fiberglass sleeves may incorporate sustainable practices and materials, reducing environmental impact.

C. Market Growth and Demand

The demand for polyacrylate fiberglass sleeves is expected to grow as industries continue to seek reliable and durable protective solutions. This growth will likely drive further innovation and development in the field.

VII. Conclusion

In summary, polyacrylate fiberglass sleeves are essential components in various industries, providing protection and insulation against heat, chemicals, and mechanical stress. The popular models discussed in this article, including high-temperature resistant, chemical-resistant, electrical insulation, fire-resistant, and customizable sleeves, each offer unique advantages tailored to specific applications. As technology advances and industries evolve, the future of polyacrylate fiberglass sleeves looks promising, with innovations in material science and a focus on sustainability paving the way for enhanced performance and reliability.

Choosing the right model of polyacrylate fiberglass sleeve is crucial for ensuring the safety and efficiency of applications across multiple sectors. As we look ahead, the continued development of these materials will play a vital role in meeting the demands of modern industries.

VIII. References

A. Academic Journals

B. Industry Reports

C. Manufacturer Specifications and Catalogs

This comprehensive overview of polyacrylate fiberglass sleeves highlights their significance, popular models, and future trends, providing valuable insights for professionals and industries that rely on these innovative materials.