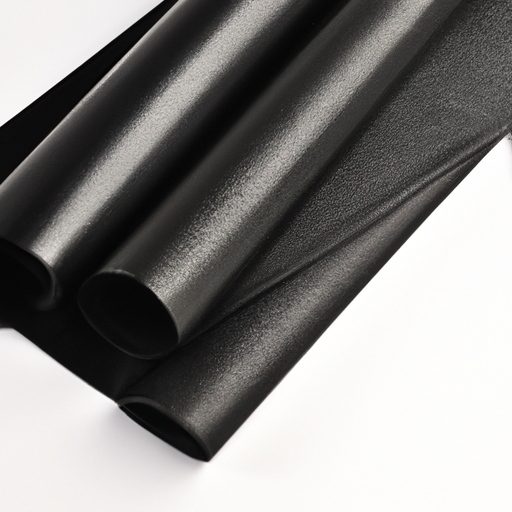

Telescopic woven sleeves are a popular choice for protecting and organizing cables, wires, and hoses in various industries. These sleeves are made from high-quality materials such as polyester, nylon, or polyethylene, and are designed to provide excellent abrasion resistance, flexibility, and durability. Mainstream telescopic woven sleeves are available in a wide range of sizes, colors, and configurations to meet the specific needs of different applications.

Another important parameter to consider is the length of the telescopic woven sleeve. These sleeves are typically sold in standard lengths, but can also be custom-cut to fit specific requirements. The length of the sleeve should be chosen based on the length of the cables, wires, or hoses that need to be covered, as well as the amount of protection required. Mainstream telescopic woven sleeves are available in lengths ranging from a few inches to several feet, providing flexibility and versatility for different applications.

Material composition is another key parameter to consider when selecting a telescopic woven sleeve. Mainstream sleeves are typically made from high-quality materials such as polyester, nylon, or polyethylene, which offer excellent abrasion resistance, flexibility, and durability. These materials are also resistant to chemicals, oils, and UV radiation, making them suitable for use in a wide range of environments. It is important to choose a sleeve made from a material that is compatible with the specific application requirements to ensure optimal performance and longevity.

Color options are also an important parameter to consider when selecting a telescopic woven sleeve. Mainstream sleeves are available in a variety of colors, including black, white, blue, red, and yellow, among others. Choosing the right color can help with organization and identification of cables, wires, and hoses, as well as provide a professional and aesthetically pleasing appearance. Some sleeves also come with color-coded stripes or markings for easy identification of different components.

In addition to the above parameters, other factors to consider when selecting a telescopic woven sleeve include temperature resistance, flame retardancy, and ease of installation. Mainstream sleeves are designed to withstand a wide range of temperatures, from -40°C to 125°C or more, making them suitable for use in both indoor and outdoor environments. Flame-retardant sleeves are also available for applications where fire safety is a concern. Installation of telescopic woven sleeves is typically quick and easy, requiring no special tools or equipment.

Overall, mainstream telescopic woven sleeves are a versatile and reliable solution for protecting and organizing cables, wires, and hoses in various industries. By considering parameters such as diameter range, length, material composition, color options, temperature resistance, flame retardancy, and ease of installation, users can select the right sleeve for their specific application requirements. With their high-quality construction and excellent performance characteristics, mainstream telescopic woven sleeves are a popular choice for a wide range of applications.